Please ask for samples!

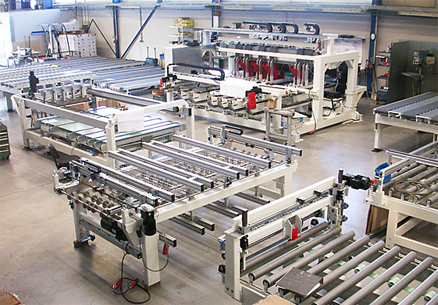

Production plant

Feeding and Stacking

A finishing line can operate perfect only, once important modules like feeders and stackers are implemented wisely.

Stackers and feeders appear quite often in various solutions and design to optimize and secure the production flow.

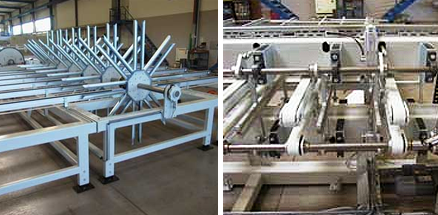

It can range from a simple charging aid for feeding, to a complicated process assistant.

Depending on which processes are being required, like accumulating, separating, turning, flipping, sorting, accelerating or decelerating, feeder and or stacker appear in a simple or complicated solution. These items can be linked together for complex systems.

The question, which module is being finally selected, depends on the product specification.

Whereas, these items should be selected individually in accordance to customer requirements and economic sense.

Merging of products

Accumulation of goods

Described items should be linked together electronically by a sophisticated machine- and line control.

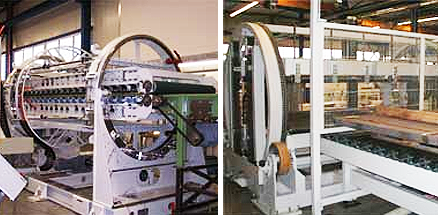

High speed flipper

Star cooler and Through feed flipper

Depending on his line intelligence, the operator can control and follow up at any time, where his products are in the production process.

It is common and standard that production stages can be documented at any time.

Storage and retrieval system

Not only that the products and its process are being controlled, the state of technology allows at any time a diagnostics routine of the entire machine line.

Remote maintenance and line diagnostics can be carried out over the internet.

Expensive services activities combined with long machine down times belong to the past.

From any computer of the world, diagnoses can be done, once both systems are being linked together.

Major line mistakes, mostly caused by human error, can be solved easily.

Localization and identification of faulty machine parts can be detected online.

Spare parts can be assigned uniquely and can be brought on the way to the customer quickly.

Feeding unit

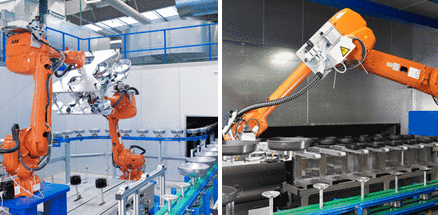

Robot feeding

These processes are just a brief projection of projects, implemented from companies as seen on our pages, to provide outmost quality, increasing process reliability and cutting the processing time to make the process as uniform as possible.

Products -> Feeding and Stacking ->